|

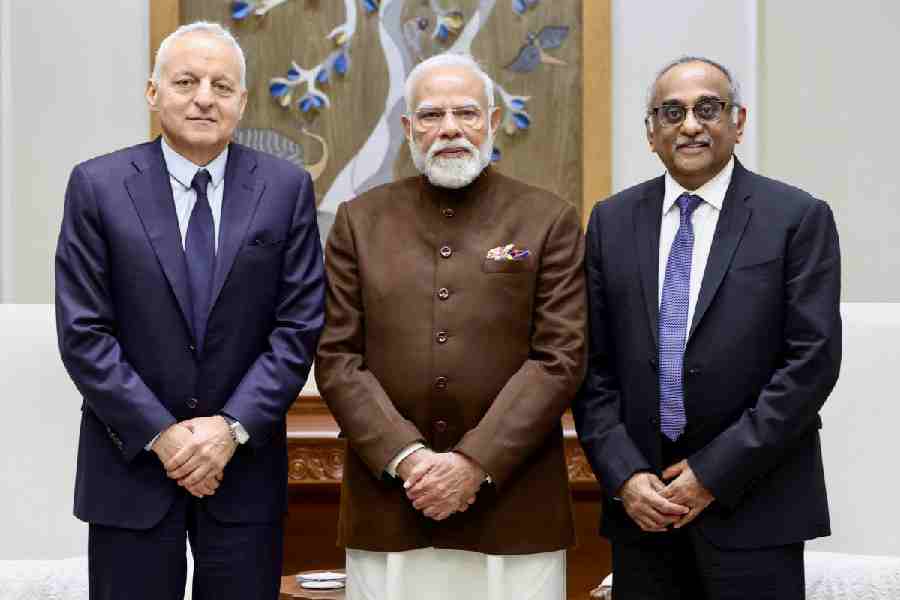

| Ties designed by Kuber Sircar |

|

lTied up in knots trying to achieve that perfect lump on the throat? Try a wooden tie for good measure.

You read it right. Devised by septuagenarian Kuber Sircar, this unique garment promises to rival its cloth counterpart in durability and easy maintenance while retaining the flexibility of a normal tie.

The retired UP Export Corporation officer hit upon the idea while watching a Nepali youth flaunt a wooden block on his chest looped with rubber strings, for a little flexibility.

“I thought there must be a way to improve upon the idea and started tinkering around with pieces of wood to while away time after my retirement,” says Sircar.

What started as a hobby has become an acclaimed craft. And Sircar has gone on to win the national award for wood carving for two consecutive years, 2001 and 2002.

Word travelled fast and before long he started receiving bulk orders from places as far as Stockholm. Unfortunately, Sircar hasn’t been able to match supply with demand as he makes the ties almost single-handedly in his Salt Lake residence-cum-workshop.

“I tried to rope in a few carpenters and even unemployed youngsters to help me in this endeavour, but I find most young people lacking the patience to persevere with this craft,” rues Sircar.

So he continues the lone crusade that requires elaborate operations like chiselling the wood into the shape of a tie, rubbing it with sandpaper to achieve the required width and gradient, carving out designs and painting it in the desired colours, and finally drilling pin holes, cutting grooves and interlocking each groove with piano steel for flexibility.

The wood used is mostly mahogany, shagun, neem and sometimes even ebony. Sircar usually “dreams” up the elaborate designs carved on the ties and mostly uses vegetable dyes and wood varnish for colour. “I stick to natural colours as most foreigners are finicky about toxic agents,” explains Sircar.

The finished product measures 2 mm in width and 10 to 13 mm around the knot area. A wooden tie weighs 40 to 100 gm as opposed to a cloth tie that weighs 25 to 30 gm. “The subtle difference in weight doesn’t matter as you don’t really feel it on that part of the body,” smiles Sircar.

He has taken ample care to lend a degree of flexibility to his work by introducing the grooves. “The more grooves per tie, the better. I usually impart 15 to 16 grooves a piece.”

A couple of chisels (some designed by Sircar himself) and a jewellery saw to cut the grooves have been the humble tools of his trade so far but he is now planning to acquire a German groove-cutting machine to make his task simpler.

“Now, it takes me three to 15 days to make a single tie depending on the richness of the carvings. With technical assistance (for which Globsyn Technologies has shown interest) I can speed up the production,” says Sircar, who is otherwise “quite content” to be pursuing the craft for pure pleasure.

“My only interest in popularising this craft is that young people find a viable profession,” says Sircar. And a lucrative one at that, considering that some of his exquisite works — like the ‘galaxy tie’ — sold for Rs 7,000 a piece.

At the moment, Sircar is keeping his fingers crossed for the results of the Seal of Excellence competition organised by the UNESCO where participants from SAARC countries display their innovative arts and crafts. If he wins, Sircar will be flying off to the Maldives in September. Shall we say, touch wood?