|

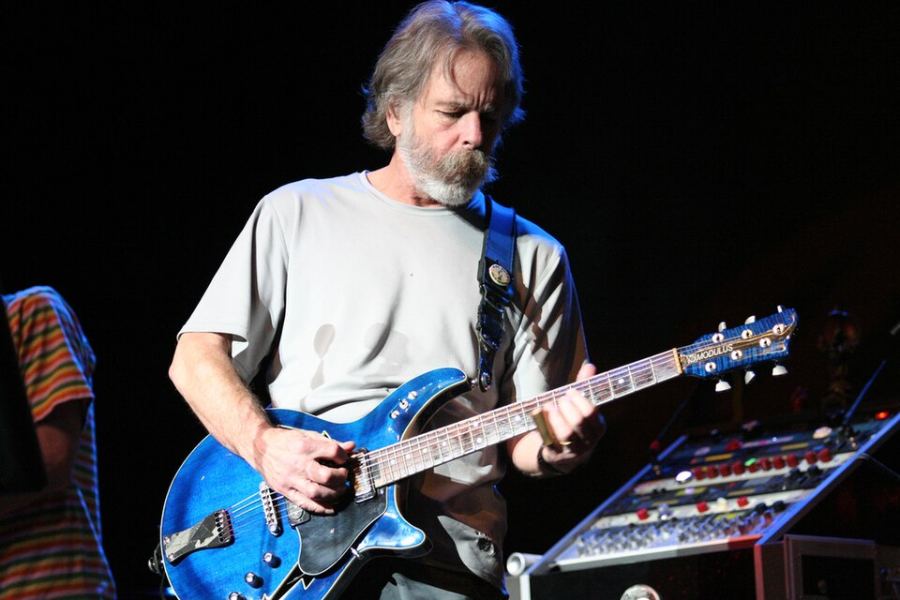

| T.C. Bhuyan (centre) with faculty of ASPEE College of Horticulture and Forestry visit a bamboo grove in Gujarat. Telegraph picture |

Jorhat, Oct. 10: Gujarat is looking towards Assam to boost its bamboo production with an eye on its multi-million rupee kite-making industry.

T.C. Bhuyan, senior scientist and a bamboo expert at Rain Forest Research Institute in Sotai, 14km from here, was called to the western state recently to inform researchers and farmers about the different varieties of bamboo which would make the kite base more strong and pliable and give a boost to the bamboo industry in Gujarat.

In a workshop-cum-training on “bamboo for the rural farmer” held at the ASPEE College of Horticulture and Forestry under Navsari Agricultural University, Bhuyan introduced three bamboo varieties for cultivation in Gujarat, which could add to the quality of kites.

“The artisans of Gujarat are involved in making bamboo products mainly with two species — Bambusa bamboos and Dendrocalamus strictus. In my presentation on bamboo propagation, cultivation, management, utilization pattern and value addition, I elaborated on the different utilisation patterns of other species growing in northeastern states and emphasised on introducing these commercially important species there so they can produce various products on a commercial basis,” Bhuyan said.

He said at present, the kite-making industry was importing bamboo from the northeastern region but it was too expensive. “The industry would now like to source the material locally and Gujarat has a climate which is suitable for growing the three species which recommended owing to their pliability and strength,” Bhuyan said.

The species recommended by Bhuyan are Bambusa polymorpha, Cephalostachyum pergracile and Teinostachyum dullooa because they have longer internodes and therefore could be used to make larger kites.

In an extensive interaction with farmers, entrepreneurs, students, forest officials and scientists, Bhuyan showed how to treat bamboos with a mix of chemicals formulated at the Jorhat institute to prevent attack by pest and diseases, so the products last longer.

He also described the different methods of propagation, intercropping with other fast-growing trees as well as agricultural crops during bamboo cultivation and gave field demonstrations about nursery, propagation and harvesting methods.

Bhuyan, in-charge of the bamboo composite centre at the institute, also interacted with the artisans and familiarised them with some of the products made at the Assam institute.

“They were impressed with some of the products which I had taken there, especially a bamboo tray made in our local design. Since the artisans and a few NGOs working in this field did not have trainers to train them in making small bamboo products, they wanted to know whether a master trainer could be got from Assam,” Bhuyan said.

The centre, which has been set up with the help of the Bangalore-based Indian Plywood Industrial Research and Training Institute in 2011, has personnel to train artisans in about 50 bamboo products ranging from sofa and dining table sets to wall hangings, combs and lamp shades.

Bhuyan said in Gujarat, bamboo furniture-making was in a nascent stage but at places plantations have started and the industry could soon pick up in a big way.