|

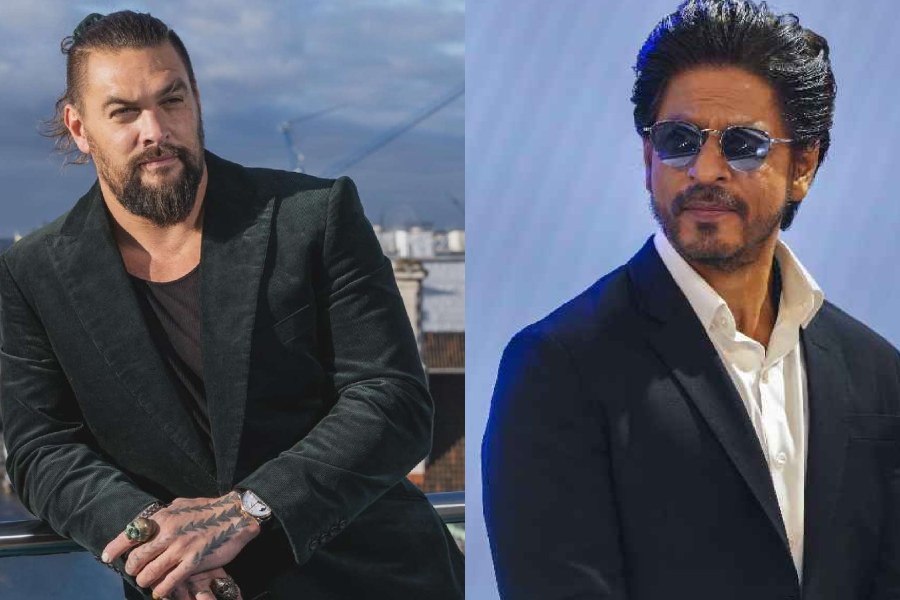

| Edwin demonstrates how the fibre is separated from the pineapple leaf. A Telegraph picture |

Bidhannagar, April 17: When chief minister Buddhadeb Bhattacharjee inaugurated the Calypso Bengal Foods, a processing factory, here in February, he had no idea that, other than the pineapple rings and juice, the plant could be of other use as well.

Neither for that matter did the company. Till a small NGO in far away Kanyakumari told its executives about twine and fabric that can be made from pineapple leaves.

Hitherto, the tuft of leaves were mostly thrown into a compost pit as it contributed to soil nourishment. But the region?s 11,000 farmers now know about the more lucrative possibilities of the leaves.

The members of the NGO, guided by the Bangalore-based trust Industree Crafts Foundation, have been perfecting the production of pineapple thread. ?They initially produced 300 m of single strand fibre in a day but can now make up to 1,000 m,? said V. Ashoke Kumar, the foundation-appointed master trainer.

He, along with instructor Shiba Edwin, is here to conduct six days of workshops at various places in Bidhannagar and Phansidewa to explain to the farmers how the leaves can be put to better use.

Samples of the fabric were brought to the Bidhannagar Kurban Ali High School for the first workshop. It looked like spun khadi silk tough enough to stitch into a shirt or a sari. ?But the cost of production is very high. The manual procedure right now puts the cost of a sq m of the fabric at Rs 2,500,? said Kumar. ?But once the twining is perfected, the cost can come down to Rs 750.?

Edwin showed how the green chlorofin was removed from the leaves by scraping them with a broken glass plate. The fibre that remained was then treated with a soap solution and dried. The single strands were then twined and rolled onto bobbins. ?We have asked IIT Chennai to develop a machine that would replace the manual procedure to make the production faster and cheaper,? Kumar said.

Calypso Bengal Foods, however, wants to explore whether the pineapple fibre can be combined with jute and made into carry bags to replace the harmful, non-degradable plastic bags. ?We have organised these workshops to impart the knowhow to the farmers,? said Vinita Mitra, Calypso?s director of HR and administration.

?Initially, we will use the leaves for combining with jute to make strong bags,? she said.