|

|

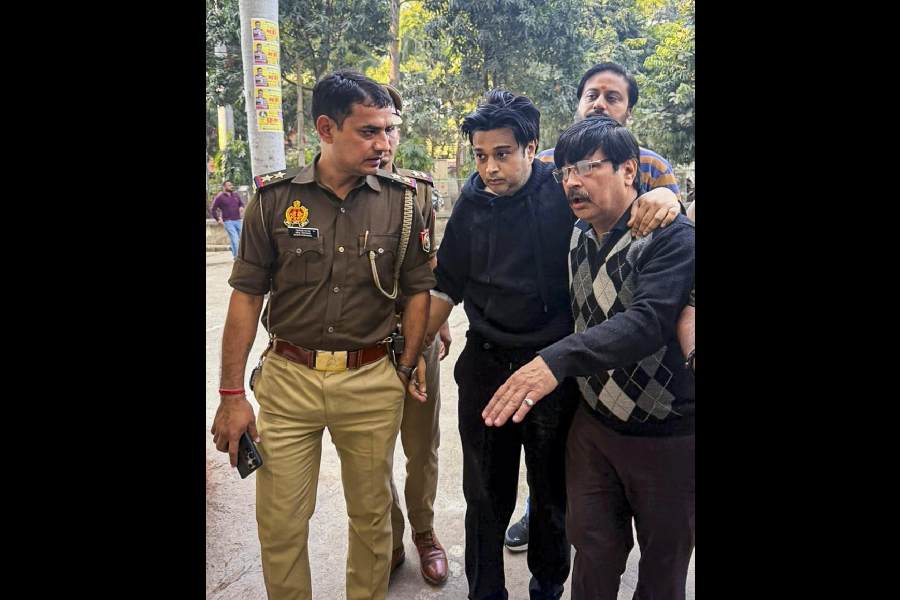

| Treasure hunt: Archaeologists at one of the Dharmapuri digs and (below) some of the wootz steel artefacts found |

|

Everyone knows of the iron pillar in the Qutub Minar enclave — it has not rusted in the 2000-odd years it has been exposed to the extreme weather of Delhi. That is because so many thousand years before the Industrial Revolution, skilled ironsmiths in India knew the trick of making iron impervious to the weather. They also knew the trick of forging good steel. This high-carbon steel was used by the sword makers of Damascus to make their strong but flexible blades, which were highly favoured by warriors.

Not surprisingly, therefore, this ability to make such high quality steel has intrigued scientists for years. British scientist Michael Faraday even tried to recreate the material in his laboratory in the nineteenth century but failed.

And though it has been known for some time that Telangana in Andhra Pradesh — primarily the four districts of Adilabad, Karim Nagar, Nizamabad, and Warangal — was one of the hot spots for the production of traditional Indian steel, popularly known as wootz steel, no detailed archaeological study of the process and tools used has been conducted there. A US archaeologist, Thelma Lowe, did visit the region in the 1980s, but she published very little on her work.

A project under the UK-India Education and Research Initiative is the first serious attempt to remedy this oversight. It aims to analyse and catalogue artefacts of archaeological significance such as implements made of wootz steel, ingots, tools and pieces of crucibles and tuyeres used in the steel making process. And archaeometallurgists from many countries, who gathered at the National Institute of Advanced Studies (NIAS) in Bangalore last week, were quite excited by the interim findings that emerged from an explorative survey by the team of Indian and British archaeometallurgists in the Telangana region over the last two years.

“This looks like a well-planned, well-thought-out research project,” says Vasant Shinde, joint director of the Deccan College in Pune, an institution known for quality archaeological studies. This is quite contrary to most archaeological research projects undertaken in India, he says.

“The picture that emerges from material evidence collected from the surface is that Telangana was part of a landscape of intense iron and steel production,” says Gill Jullef of Exeter University in the UK who, along with Sharada Srinivasan and Srinivasa Ranganathan of NIAS, is leading the project. Jullef is an experienced field archaeologist who first excavated unique wind-powered furnaces in Sri Lanka in the 1990s. The scientists, who focused on a 30-km diameter around the town of Dharmapuri on the banks of the Godavari in Karim Nagar, recorded as many as 134 sites of various activities relating to steel making or waste heaps.

What made this unique project possible, however, is the coming together of research teams from two countries that complimented each other. Another person who contributed immensely was Sriperumbudur Jaikishan, the principal of a local college in Dharmapuri, who has painstakingly documented numerous sites in the region, spending money from his pocket. Many artefacts that were being studied by the archaeologists were collected before the study began by Jaikishan, who is convinced the region was the nucleus of wootz steel production.

It all started with a chance meeting between Srinivasan, an associate professor at NIAS who has identified and studied similar wootz steel sites and archaeological artefacts in Tamil Nadu and Karnataka, and Jaikishan about five years ago. Subsequently, the NIAS and Exeter University teams decided to work together on the project and co-opted Jaikishan and Brian Gilmour, an Oxford University archaeologist who has extensively studied early iron and steel from Asia, as senior researchers.

“European accounts from the 16th century onwards have suggested that the south Indian region was a world leader in the production of a high grade crucible steel which was traded on a semi-industrial scale, especially to Persia and West Asia to make Damascus blades,” says Srinivasan. Incidentally, she and Ranganathan, a professor of metallurgy who divides his time between the Indian Institute of Science (also in Bangalore) and NIAS, wrote a book, India’s legendary wootz steel, in 2004.

“What is important is to date the crucible steel production from the region. This would help us understand whether the knowledge of crucible steel making radiated from India or came from outside,” says David Killick, an anthropologist at the University of Arizona, the US. According to him, many countries along the Silk Route were known to produce crucible steel by the medieval period.

“We will be better prepared to solve the materials problems of the future if we understand and appreciate the achievements made by traditional craftsmen in the past,” believes Ranganathan.