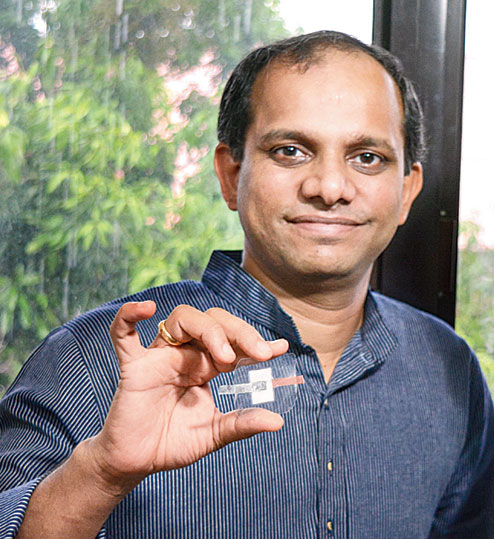

When paddy is turned into rice in the mill, the husk is discarded. This waste material is, however, of incredible value to physicist Mancheri Manikoth Shaijumon of the Indian Institute of Science Education and Research (IISER), Thiruvananthapuram. A team led by him has extracted a valuable carbon material from rice husk, paving the way for a cheaper hybrid energy storage device, a holy grail of energy technology.

Such hybrid energy devices - still a work in progress - will pack more power than conventional Lithium-ion (Li-ion) batteries and be capable of running different gadgets of varying power needs, from a cell phone and a laptop to a camera flash or an electric car. While the first two require energy supplied at a steady rate for long periods of time, the last two need a rush of energy in a split-second.

To make such an all-in-one energy device, electrochemical scientists have been trying to combine the best of two disparate energy devices - a battery, like the Li-ion battery that is used in cell phones, and what scientists call a supercapacitor, a device that can deliver a lot of power in a fraction of a second, say, to start up an electric vehicle. A supercapacitor's ability to deliver humongous amounts of power in a short span of time is so good that Airbus 380, touted as an airliner for 21st century travel, uses an array of supercapacitors to operate its emergency evacuation doors.

"Supercapacitors are electrochemical energy storage devices that capture and release energy in a few seconds. Such cycles can be repeated several thousand times. However, they are limited in terms of charge stored. They store only five per cent of what Li-ion batteries can store," says Shaijumon, who is an assistant professor of physics at IISER. Rechargeable batteries on the other hand can undergo the charge-discharge cycle only a few hundred times.

In theory, a hybrid device that holds a high quantum of energy (called energy density) and releases it in a flash (power density) can be easily designed by suitably combining the chemistries of supercapacitors and rechargeable Li-ion batteries. But that requires suitable electrode materials that can support both high energy density as well as power density. The electrodes form the positive and negative terminals of a power device. In a hybrid device, they are called battery electrode and capacitor electrode.

The IISER team, which includes Shaijumon's students Binson Babu and P.G. Lashmi, reports synthesis of one such novel capacitor electrode in a paper recently published in the journal Electrochimica Acta. What is unique about the electrode is that it was fabricated from a porous carbon material derived from rice husk through simple chemical reactions that are environment friendly. The chemical treatment makes it possible to have a large number of pores in the electrode, and this in turn helps the electrode to hold more charge. The greater the number of tiny pores, the higher the amount of charge that can be stored. The battery electrode used in the study was the one used in commercially available Li-ion batteries.

Shaijumon claims that their hybrid supercapacitor device is capable of delivering a maximum power density of approximately 9.7 kiloWatt per kg (kW/kg) and a maximum energy density of 57 watt-hour per kg (Wh/kg). But at a practical level, these numbers will be considerably low as there is a trade off between energy and power densities, he says. When power density is high, energy density is normally low, or vice versa. "Still, our device shows a very high energy density of 45 Wh/kg even at a high power density of 4.3 kW/kp, which is superior to several porous carbon-based Li-ion capacitors reported from elsewhere," he says.

Independent experts, however, say that they are not sure whether such numbers are good enough. Shaijumon on the other hand is quite confident that they would be able to further improve the device. He says both the electrodes can be further tweaked to give better values.

"Yes there is some marginal novelty (which comes from the use of rice husk), but results are not an order of magnitude better (to make it practically useful)," says K Vijayamohanan Pillai, director of the Central Electro-Chemical Research Institute, Karaikudi, in Tamil Nadu. CECRI scientists have been working to develop such hybrid energy devices for some time.

"There are many bio-inspired synthetic strategies for carbon - from coconut shell to human hair to fish scale - and a minor composition change sometimes gives fantastic properties. The values reported in this work are normal and are available with many Li-based supercapacitors. Applications for electric and hybrid electric vehicles need big breakthroughs," Pillai argues.

Ashutosh Kumar Singh, a research associate with the Bangalore-based Centre for Nano and Soft Matter Sciences, has earlier worked on hybrid supercapacitor electrodes and concurs with Pillai. "I am not very sure about their practical application claims," he says. However, he admits that the device would be cheaper than those attempted elsewhere because it is produced from a cheap, naturally-available material.