Ahead of the World Cup this year, 1.2 metric tonnes (one tonne equals 1,000 kilos) of mutton made its way to Qatar from the Haringhata meat plant in Nadia district of Bengal. The plant and the brand take their name from a small town in Nadia.

To get back to the Qatar consignment, the buyers — Dahiya Export and Import Limited — have signed a long-term contract that will entail a steady supply of sheep and goat meat, known as chevon and mutton, respectively, over a period of time.

At the Nadia plant, 300 sheep and goats are slaughtered (Haringhata meats are certified halal) every day and sent to Calcutta, from where it all moves to the 667 Haringhata outlets scattered across Bengal. At the poultry-processing plant in Haringhata, 8,000 broiler birds are slaughtered every day and 10-12 tonnes of chicken and a total of 1.5 tonnes of duck, quail and turkey meat are produced.

All of it is brought to a cold storage in Belgachia in north Calcutta and supplied in refrigerated vans to outlets in South Bengal. Twelve to 14 tonnes of poultry meat produced at Darjeeling’s Phansidewa plant is supplied to outlets in north Bengal, Sikkim and Assam. Five tonnes of pork are produced weekly at Nadia’s pork plant and sent to Belgachia’s cold storage and from there to south Bengal. Another six tonnes of pork are produced at Phansidewa’s pork plant and supplied to north Bengal, Assam and Sikkim. At Kalyani’s egg manufacturing plant, 3.2 lakh eggs are produced every day and supplied to Haringhata outlets across Bengal. Two tonnes of rabbit meat are produced twice a month — it has a low demand.

For many, even now, Haringhata is synonymous with pasteurised bottled milk. And yet, from the time it was established in 1974, Haringhata has been about meat.

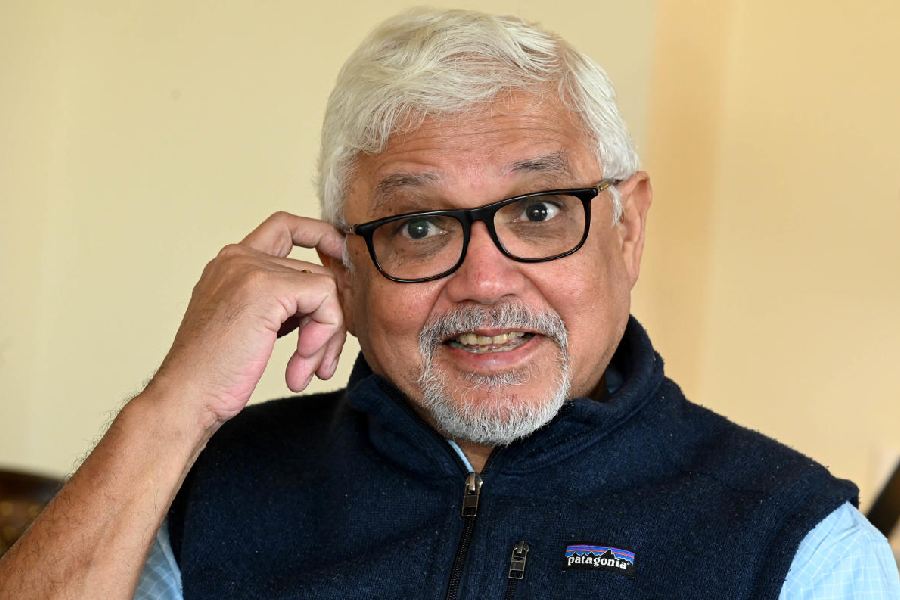

“The first plant, set up in Durgapur, was a service slaughterhouse for goats. Farmers would get their livestock slaughtered in a scientific and hygienic manner here. The service was discontinued after a couple of years,” says Gouri Shankar Koner, managing director of the West Bengal Livestock Development Corporation Limited (WBLDCL), which runs Haringhata. The boss of the corporation is the department of animal resources development, Government of West Bengal.

In 1974, the Centre-state division was 20-80. The Centre had made a one-time contribution of Rs 25 lakh. Says Koner, “Now, the Centre’s stake is 6.93 per cent as against the state’s 93.07 per cent.”

First things first. The WBLDCL took over a bacon factory and piggery in Nadia that supplied bacon and ham to Writers’ Buildings and a store in south Calcutta. This was between 1964 and 2005. Long hiatus and then in 2008-09, they opened a chicken processing centre in Nadia. A slaughter unit was opened in Belgachia. Small facilities both; limited capacities.

In 2011, the year the Trinamul came to power in Bengal, the WBLDCL launched a semi-automatic plant in Haringhata. A bigger plant, this one could slaughter half a thousand broiler birds every hour. 2015-16. Further expansion. From just slaughter to specialised cuts, and value-added products such as sausage, salami, nuggets and cutlets. The plant started running for 24 hours. The number of retail outlets went up. From six in 2010-11 to 667 until now — beginning 2016-17, Haringhata has added 50 outlets every year.

Today, there are outlets in every district of Bengal. “We also supply meat outside Bengal such as to Delhi, Andaman and Guwahati,” says Koner. Haringhata used to supply 14 tonnes of pork every month to Bhutan in 2017-18. That stopped due to Covid-19.

The cost of procuring chicken is high, so the WBLDCL decided to raise its own poultry. Farmers were roped in and provided with chicks and feed for 35-40 days, vaccines and necessary medicines. This project was called the entrepreneurship development programme. “It employed 1,000 people directly and another 15,000-20,000 people indirectly,” says Koner.

This was 2017. By 2018, Haringhata got into the hotel-restaurant-catering chain and started supplying meat to the airline catering company Taj SATS and the Taj Bengal chain of hotels in West Bengal — Taj Bengal in Alipore, Taj Vivanta at the Ruby crossing, Taj Tal Kutir in New Town, Taj Chia Kutir in Makaibari, Darjeeling. Retail chains such as BigBasket, Metro Cash & Carry and More also started stocking Haringhata meat.

The next step was to contain wastage. Haringhata built a 30-metric-tonne central cold storage at Belgachia. The pork factory at Nadia’s Haringhata is running; only production is now five tonnes of meat a week. A second factory has come up in Phansidewa to avoid the transportation cost to north Bengal and the northeastern states. A unit of broiler breeding-cum-hatchery was started in Jotiakhali in north Bengal; it produces 50,00,000 chicks annually.

In the meantime, a merger has taken place between the WBLDCL and the West Bengal Dairy and Poultry Development Corporation Ltd or Dairpoul. “They [Dairpoul] manufacture poultry feed. Now we do not have to buy feed any longer,” says Koner.

In 2017-18, Haringhata decided to promote Bengal’s black goat. A goat plant came up. Exporters started getting in touch with the WBLDCL. Once the Agricultural and Processed Food Products Export Development Authority (Apeda) gave the nod in September this year, a memorandum of understanding was signed between the WBLDCL, Dahiya Import and Export Limited and the Apeda. “Dahiya is in touch with buyers in Qatar who are supplying meat for the Fifa World Cup,” says Koner.

Now the task is to maximise production of mutton. “There will be no dearth of supply to the local market as we are currently underutilised. We just need to increase our shifts. Also, we are roping in farmer-producer companies — small entities formed by primary producers — who are going to breed the goat and supply us,” he says.

Brand Haringhata continues to burgeon. A commercial poultry layer farm was launched in Kalyani in 2019-20. Says Koner, “To date, eggs are imported from Telangana and Odisha. We need about 47 crore eggs annually for the mid-day meal scheme, child development and maternity care. But we will be able to meet this demand after 2023 as we are setting up poultry layer farms in Coochbehar, Malda, Haringhata, Salboni, Bankura, Purulia and Kalyani.” Haringhata is also producing laboratory meat for science experiments — rabbits, mice, rats, guinea pigs, hamsters, zebrafish — and supplying them to educational institutes for research. He adds, “That’s a different story, for another time.”