|

The path-breaking work being done at physicist Arindam Ghosh’s lab at the Indian Institute of Science (IISc) in Bangalore may revolutionise your digital life.

An ultra-thin composite material that Ghosh and his colleagues, including his doctoral student Kallol Roy, have created could make digital cameras about a billion times more sensitive, turn memory devices faster and and make them long lasting and produce solar cells that generate more electricity for a given area, not to talk of a plethora of potential applications in defence and deep space exploration.

The work, which appeared in the journal Nature Nanotechnology yesterday, is more gratifying for Ghosh and his team because they beat many prominent research groups to it, including one at global IT giant IBM.

This is a brand new design that exploits the properties of two different materials — the conductivity of graphene and the photosensitivity of molybdenum disulphide — that are used to make the composite material which is less than 2 nanometre (nm) thick, says Ghosh. In comparison, the thickness of a sheet of paper is about 100,000 nm.

Graphene is a form of carbon in which the atoms are arranged in a flat hexagon lattice-like microscopic chicken wire, a single atom thick (roughly 0.3 nm). It is not only the thinnest material in the world but also the strongest. Besides, it can conduct electricity and heat better than any other known material.

|

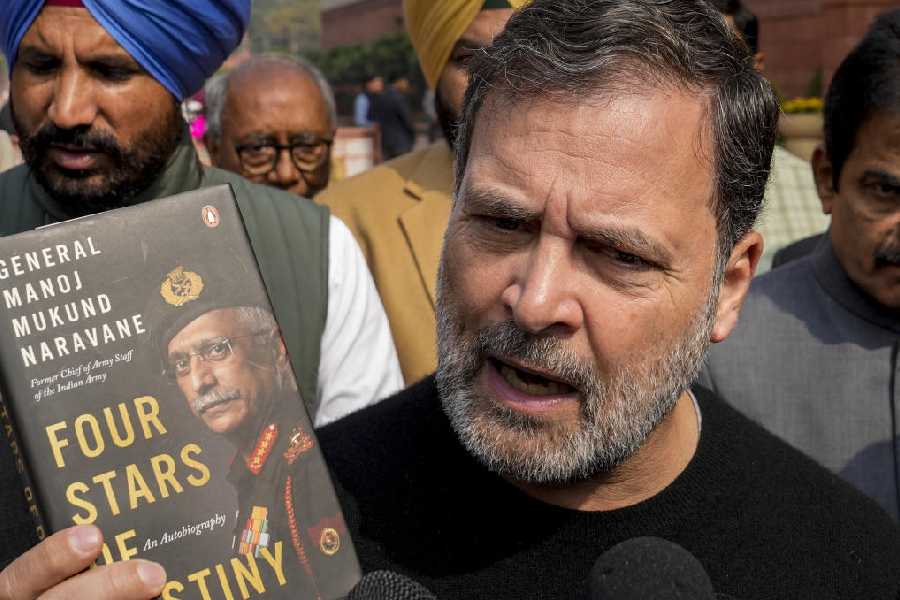

| Arindam Ghosh and (top) the composite chip his team created |

This wonder material, which won two University of Manchester scientists a Nobel prize in physics three years ago, is believed to rival silicon as a basis for computer chips and take electronic applications to a level beyond the collective imagination of humankind. However, its potential as a photosensitive material is rather limited. This serious handicap can impede its use in diverse fields of photodetection, photovoltaic cells and high-speed optical fibre-based data communication.

The Bangalore scientists, however, overcame this handicap by sandwiching graphene with molybdenum disulphide, which readily gives out electrons when light falls on it. These electrons can then move to the adjoining graphene layer and stay there as long as it is connected to a power source.

“We foresee two major applications for this material,” says Ghosh, who studied at Ballygunge Government High School before graduating in physics from St Xaviers College, Calcutta.

“This is the most sensitive light detector that humans have ever made. Theoretically speaking, it can detect a candle lit thousands of kilometres away. This means that it makes photography possible in extremely dim light. The possibilities that it offers in areas like night vision equipment and target-seeking weaponry systems are tremendous. This feature could also be exploited to design superior telescopes that capture faint light from the farthest of galaxies,” Ghosh told KnowHow.

A typical digital camera uses a silicon-based image sensor (a silicon chip that can capture and read light) which has a sensitivity of around 1 Ampere per Watt. That is, if you shine light of 1 microwatt intensity (roughly 1,000 times less intense than candle light) it will cause a change in the current through the device by one microampere. The cameras measure this change in current and form the image. In the case of the new material, this change is about one billion times larger (that is, in principle one can measure a change of 1,000 ampere from one microwatt power). Hence compared to the existing technology of silicon image sensors, these devices are about one billion times more sensitive, and you can detect objects that are far fainter because of the distance.

The second aspect is its potential in making memory devices last longer. “A USB if not in regular use stores data typically for one or two years. We hope that the devices made of the new hybrid material could store memory for tens of years,” says Ghosh, an avid cricket player who played for IISc for 14 years — first as a student and then as a faculty member.

|

“What is also important is the composite is like a sheet, which can be rolled up just like a mat. Since it is flexible, it can even be applied on curved surfaces,” says Roy, the first author of the paper. Roy hails from a village called Dighara in Hooghly district and studied in a village school till Class XII.

“This is a very nice demonstration and takes graphene-based optoelectronic devices a solid step closer to reality,” says Fengnian Xia, an electrical engineering researcher at Yale University in Connecticut, who was till recently with IBM’s Thomas J. Watson Research Centre, which is developing similar graphene-based technologies. One of the immediate potential applications that Xia foresees is in cameras currently available on smart phones.

“What is special about this work is that it exploits the unique properties of two-dimensional materials like graphene and molybdenum disulphide. They can be made on a very large scale and potentially cost much less than metal-oxide or silicon-based photodetectors [which are currently used in digital cameras],” he says.

However, the Yale University scientist adds: “At the same time, we have to understand that a single important breakthrough or innovation will not change our life dramatically. With more efforts and innovations like this, I am sure one day such materials will change our daily life.”

When that happens, this Indian team’s contribution would be right at the top.