|

|

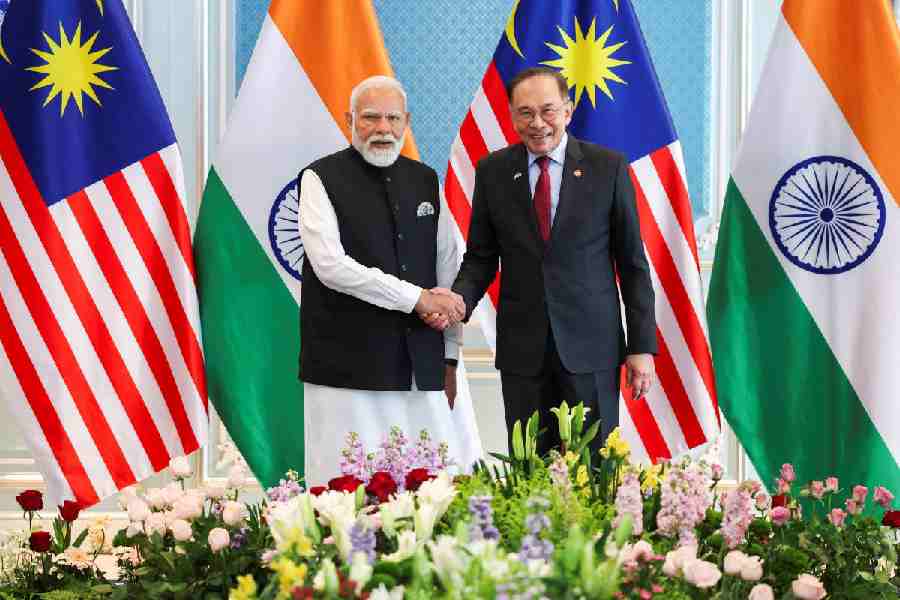

| The chemical process to extract high-value silica nanocrystals from rice husk |

Researchers in Pune have enlisted the services of a commonly found fungus to rip a high-value industrial chemical from a cheap, abundantly available waste material: rice husk.

Silica, or silicon dioxide, has a wide range of commercial and industrial applications: in the manufacture of resins and molecular sieves (materials with tiny pores of precise and uniform size that can absorb gases or liquids in industrial processes), and as catalysts for several industrial chemical reactions. An exciting biomedical foray was also thrown open early this year when scientists found that the use of silica nanoparticles can enhance the image quality of tumour cells, making it possible for an ultrasound device to track them and thereby detect cancers.

Being the oxide of silicon, the second most prominent element on earth after oxygen, silica is present in many things around us: sands, rocks and even some plants, including rice. About 10 per cent of rice husk — the outer casing of rice grain — is known to be composed of silica. But the form in which it is present in rice husk does not make it readily usable — it’s nebulous and shapeless, while the silica that is required in industrial processes is crystalline and more precisely made into tiny, uniformly structured nanoparticles.

Currently, the processes by which silica nanoparticles are manufactured from amorphous silica involve high temperatures of up to 1500 degrees and several times of normal atmospheric pressure. Needless to say, such methods are relatively expensive and unfriendly to the environment.

Now, a team of researchers from the Pune-based National Chemical Laboratory (NCL) and Tata Chemicals Innovation Centre have, at least at the laboratory scale, shown that this need not be the case. Using the fungus Fusarium oxysporum, commonly found in garden soil, they demonstrated that almost the entire silica present in rice husk (up to 97 per cent) can be converted to high value nanocrystals of two-six nanometres in size. More importantly, the entire operation takes place at room temperatures.

Incidentally, this research group has been using F. oxysporum and several other microbes to extract valuable nano-scale material from cheap raw material. Recently, they reported success with barium titanate, a wonderful ferroelectric “memory” material that is much sought after by the microelectronics industry. Again, a couple of years ago, they trained a particular bacteria to produce gold and silver nanoparticles.

The presence of silica in rice husk was known for more than six decades. “It’s surprising that there have been no attempts at harnessing the enormous amount of silica present in rice husk, despite the substance’s ever-growing demand and new-found applications,” says Absar Ahmad, a scientist at the biochemical division at NCL. Ahmad, along with Vipul Bansal of NCL and Murali Sastry of Tata Chemicals Innovation Centre, reported the findings in the recent issue of Journal of American Chemical Society.

“The key thing here is the transformation of silica to a highly useful form at room temperatures without involving any apparent cost,” says Kailathuvalappil Inniri Vasu, metallurgist and former director of the Karaikudi-based Central Electrochemical Research Institute. “Everyone knows that the ash retrieved by burning rice husk harbours substantial amounts of silica, but this is not of much industrial use. The Pune researchers have shown that they can transform this into uniform-sized nanoparticles of silica through bioleaching, and this is very significant,” he observes. According to Vasu, such silica nanoparticles are important not just in big-buck industrial applications but also in normal life processes, for instance, in water purification.

P. Pradip, a materials expert at Tata Research Development and Design Centre, calls this “an exciting chemistry”. Producing advanced material in inexpensive ways has always been of great interest. But to become an industrially accepted technique, it has miles to go, he feels. What they have demonstrated is still at a lab scale with the quantities involved being a few grams. To be commercially viable, the process has to be scaled up to producing a few kilograms, if not tonnes.

Such scaling up always throws up a lot of challenges. For example, producing and maintaining microorganisms in quantities required for an industrial process may not be easy. Similarly, the time required for the biotransformation may not be optimal. For instance, in this work, fungi take about 24 hours to convert amorphous silica into nanocrystalline silica. Industries may find this exceedingly slow, says Pradip. Moreover, waste disposal could also be an issue.

Pradip, however, asserts that these are not scientists’ problems and must be worked out by research and development managers of firms interested in such novel processes.

In the meantime, a number of firms have evinced keen interest in working with the Pune scientists to explore the commercial viability of the process, informs Ahmad.

Apart from the process itself, what might be attracting industrial attention is the fact that the raw material required for this fungus-mediated production is a cheaply available agro-based waste material, something that is hardly put to good use. It’s either used in cattle feed or as a biofuel. India, the second highest rice grower in the world, produces nearly 90 million tonnes of the cereal annually. Considering that 20 per cent of the grain weight is husk, the raw material available is plenty.

The Pune scientists feel that this sort of room-temperature synthesis of oxide nanomaterials using microorganisms starting from cheap agro-industrial waste material is an exciting possibility. This, they claim, could lead to an energy-conserving and economically viable green approach toward the large-scale synthesis of oxide nanomaterials.