Monday, 06 May 2024

Monday, 06 May 2024

Monday, 06 May 2024

Monday, 06 May 2024

Gear up for Baahubali’s animated spin-off

The second season of ‘Nikhoj’ is officially underway

Get trendy with this Ayushmann Khurrana-approved lifestyle brand

Don’t miss Nussrat Jahan’s hilarious attempt at using chopsticks

Beat the heat with chef Kunal Kapur’s Rose Mojito recipe

Let us reflect on some hard realities of contemporary India. ‘Mere’ corruption is no longer an electoral issue: we do not shun politicians because they might have their hands in the till or in our pockets

SUKANTA CHAUDHURI

Epidemic Plan, envisioned as a collaborative endeavour among the Central govt, state governments, and relevant stakeholders, aims to provide a comprehensive blueprint for coordinated action

BASIL GUPTA

The attitude of the West to its Muslim citizens is beginning to mirror their hostility towards non-client Muslim states abroad. Some of this is a hangover of the ‘war on terror’ since 9/11

MUKUL KESAVAN

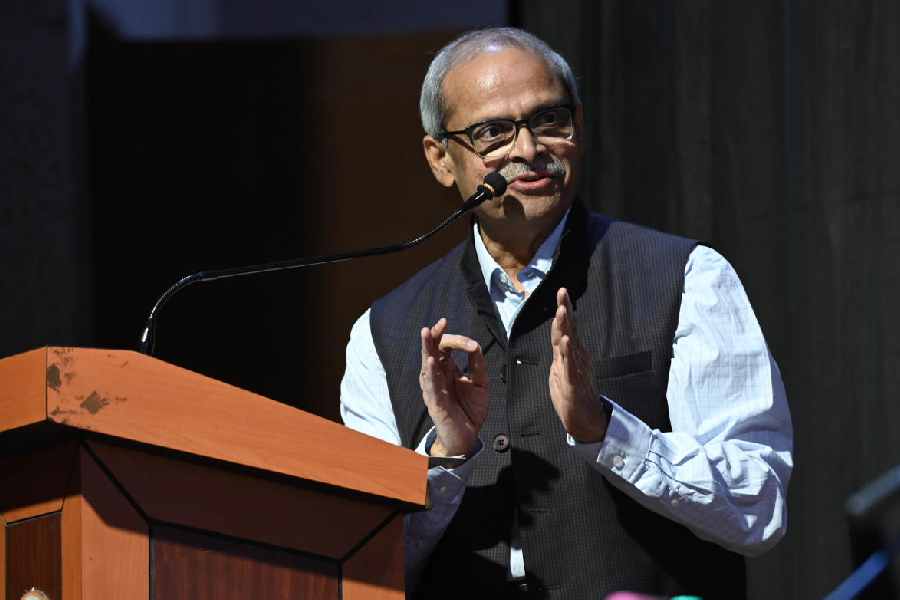

The ideological penetration of Indian science by Hindutva was starkly illustrated by a series of nine linked tweets issued by the secretary of the department of science and technology last month

RAMACHANDRA GUHA

Tapping into the state’s economic potential must also be a representative process. Unity, rather than uniformity, should be the preferred goal while restoring normalcy to Manipur

THE EDITORIAL BOARD

The British actor who also sings and woos Anne Hathaway in The Idea of You is becoming an impressive romantic lead of this generation