Tuesday, 14 May 2024

Tuesday, 14 May 2024

Tuesday, 14 May 2024

Tuesday, 14 May 2024

Nussrat’s li’l munchkin Yishaan makes social media debut on Mother’s Day

Taimur and Jehangir help Kareena polish off her Mother’s Day cake

It’s ‘family funday’ for Priyanka, Nick and li’l Malti Marie

Akshata Murty plays ball with school kids at 10 Downing Street

Stand-up comedian Shane Gillis is the face of new Netflix comedy, ‘Tires’

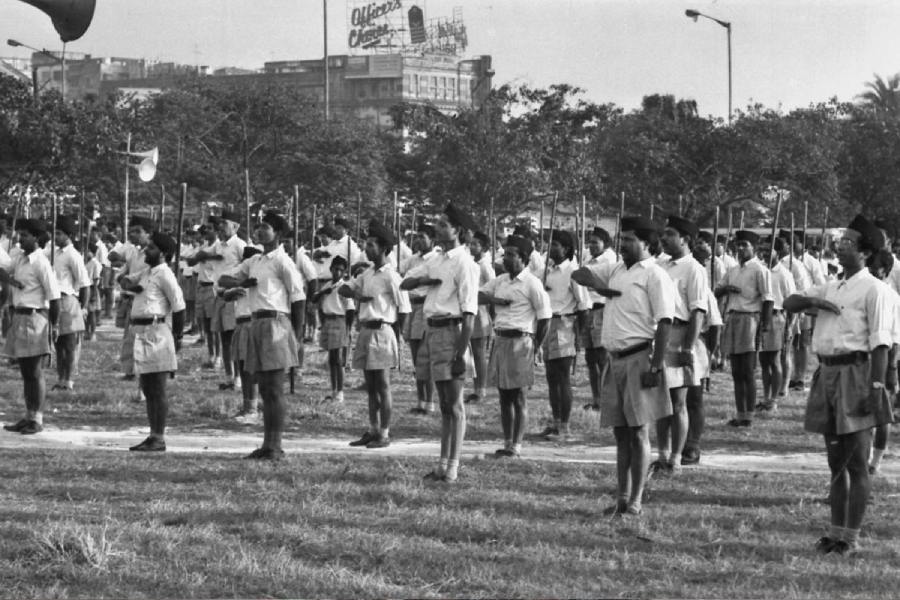

Rather than zooming into this fleeting moment of two months, an imaginary zooming out might allow us to see these elections and their ramifications in the context of the recent past and the near future

RUCHIR JOSHI

The first Indian recording made commercially in Calcutta took place on Nov 8, 1902. The singers were two nautch girls, Sashi Mukhi & Feni Bala, from Amarendra Nath Dutta’s Classic Theatre

MOUSUMI ROY

Kissinger argued that inherently unpredictable military applications of AI might eventually undermine even the minimal strategic stability of nuclear deterrence among the US, China and Russia

TIMOTHY GARTON ASH

An FTA with the United Kingdom is in the works; once implemented, the UK-India FTA will be the first such free trade agreement that India would have with a major Western power

PRANAY SHOME

If it is a political conspiracy, as the governor claims, it would be easiest to dispose of it by exposing the falsehoods. But his actions have added fuel to the chief minister’s attacks against him

THE EDITORIAL BOARD

21-year-old Arhaan Khan studied filmmaking in the US; his podcast Dumb Biryani is streaming on YouTube